IDV: Safety valves with a significantly higher flow rate

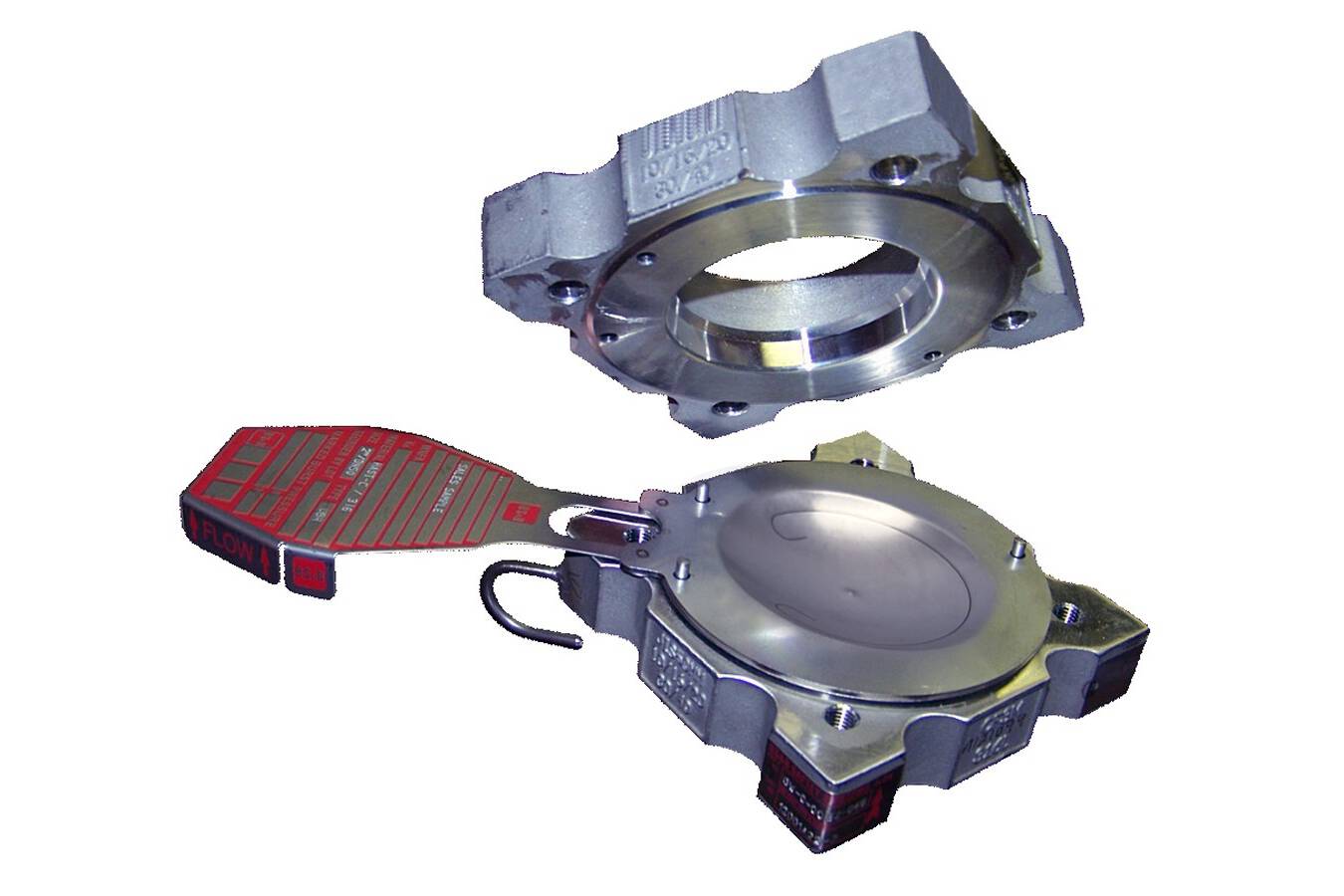

Depending on their size, the IDV safety valves with inline design from Bormann & Neupert by BS&B offer up to three times the flow capacity of conventional safety valves and are particularly compact and lightweight.

Pressure relief valves protect production, transport and storage facilities in the chemical industry and process engineering from the dangers of unauthorised overpressure. Precise response behaviour and high flow capacities are decisive factors for functional safety, efficiency and economy. Thanks to its inline design, the IDV safety valve from Bormann & Neupert by BS&B offers up to three times the capacity of a conventional API safety valve that fulfils the same regulations and standards.

Thanks to the increased flow capacity gained, engineers and operators are able to optimise their pressure safety systems and reduce the pipe configuration by one or more nominal sizes in many applications.

Less weight, dimensions and costs

Both connection flanges of the IDV valves - available in accordance with ANSI/ASME B16.5 or DIN - have identical dimensions and are in line. They can be mounted both horizontally and vertically, which further increases application flexibility. The IDV valves are also smaller and, depending on the diameter, up to 50 per cent lighter than other designs. This means that protection systems can be made more compact, simpler and more cost-effective overall.

The basic function of the IDV valves corresponds to that of classic safety valves: when the fixed response pressure is reached, the spring-loaded valves open the relief cross-section with absolute reliability and high precision. Once the process pressure drops to a non-critical level, they close automatically. The set pressure is independent of the back pressure, which is why the valves are also very suitable for applications with variable back pressure. They are available in nominal sizes from 1 to 10 inches and with set pressures from 15 to 500 psi (1.03 to 34.4 bar).

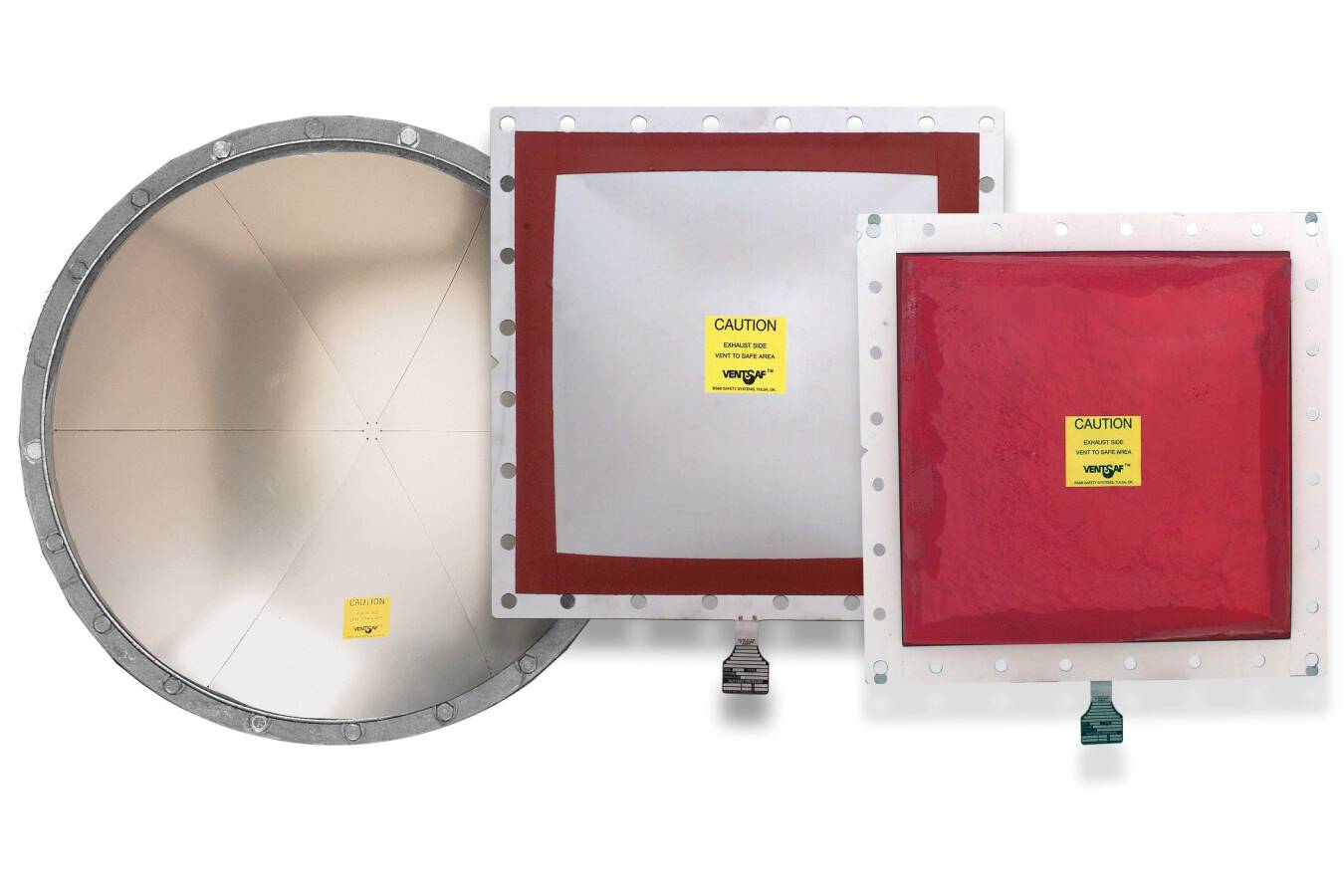

Even better with integrated rupture disc

The IDV safety valves can optionally be combined with an integrated rupture disc at the inlet or outlet as well as at both connections. This combination offers additional advantages resulting from the valve insulation compared to normal process conditions. These include optimum tightness, increased operating pressure, extended valve service life, reduced valve maintenance, improved corrosion resistance, reduced thermal footprint and increased reliability.