Attend this one day course at the Wolfson Centre premises in the UK to learn about Rotary Valves.

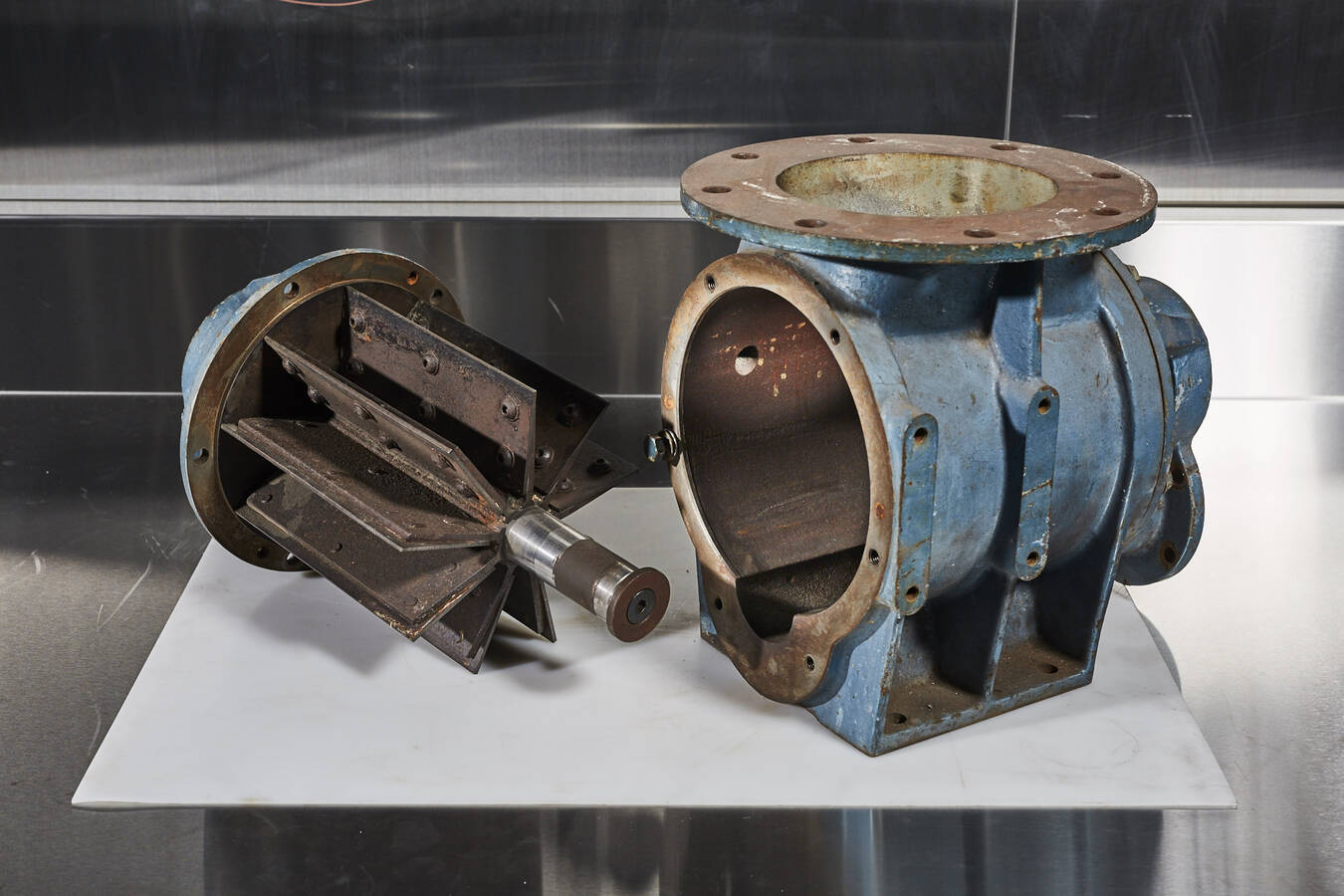

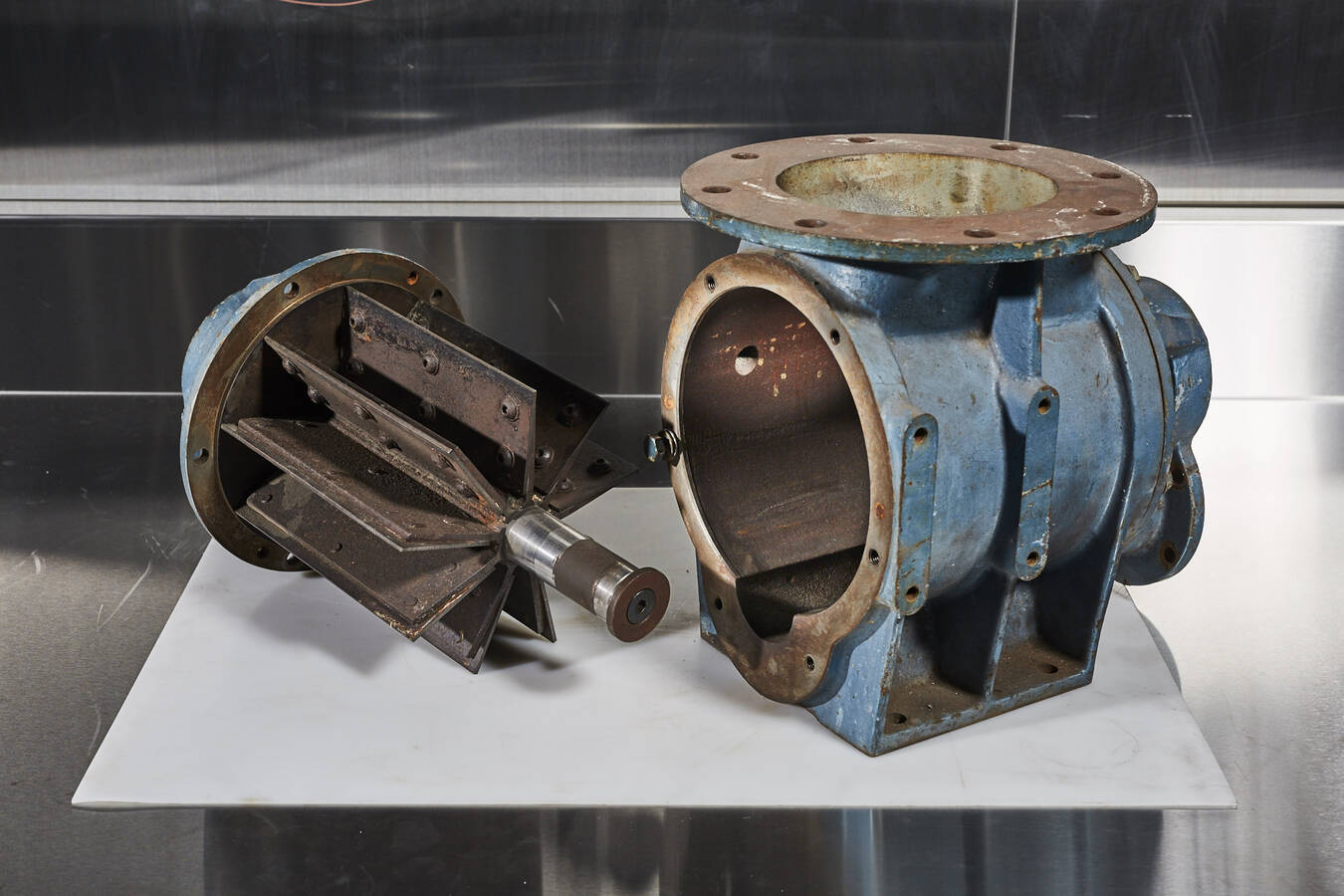

Rotary valves are widely used to feed pneumatic conveying pipelines, and for feed metering, explosion isolation, atmospheric isolation etc.

However there are literally thousands of combinations of different feature options available covering choice of materials of construction, rotor type, drive type, venting arrangements, bearing pattern, seal choice, clearances, cleaning features etc.

This course is designed to help untangle all the different options to allow correct selection for your plant.

Topics include:

- Application areas for rotary valves, and their different demands (feeding, explosion protection, isolation etc)

- Basics of rotary valve performance – air leakage, feed rate etc

- Materials of construction linked to issues of wear and build-up

- Seals and bearings, options, functions and selection

- Special consideration for explosion isolation

- ATEX requirements and responsibilities

- Features for cleaning and preventing contamination

- Venting – needs, options and ensuring success

- Review of practical application issues

There will also be a practical demonstration of different valves from an Industry expert.