Pulverhandhabung und Pulverfluss für die additive Fertigung

Online-Kurzlehrgang.......coming up Auch in diesem Jahr arbeitet das Wolfson Centre for Bulk Solids Handling Technology mit einigen der führenden Experten der Additive Manufacturing-Industrie zusammen, um die Teilnehmer durch die potenziellen Probleme zu führen, die bei der Handhabung von Pulvern im Rahmen des AM-Prozesses auftreten.

Präsentationen des Fraunhofer IFAM Instituts in Bremen und von Carpenter Additive werden neben Beiträgen der University of Greenwich und des Wolfson Centre gehalten.

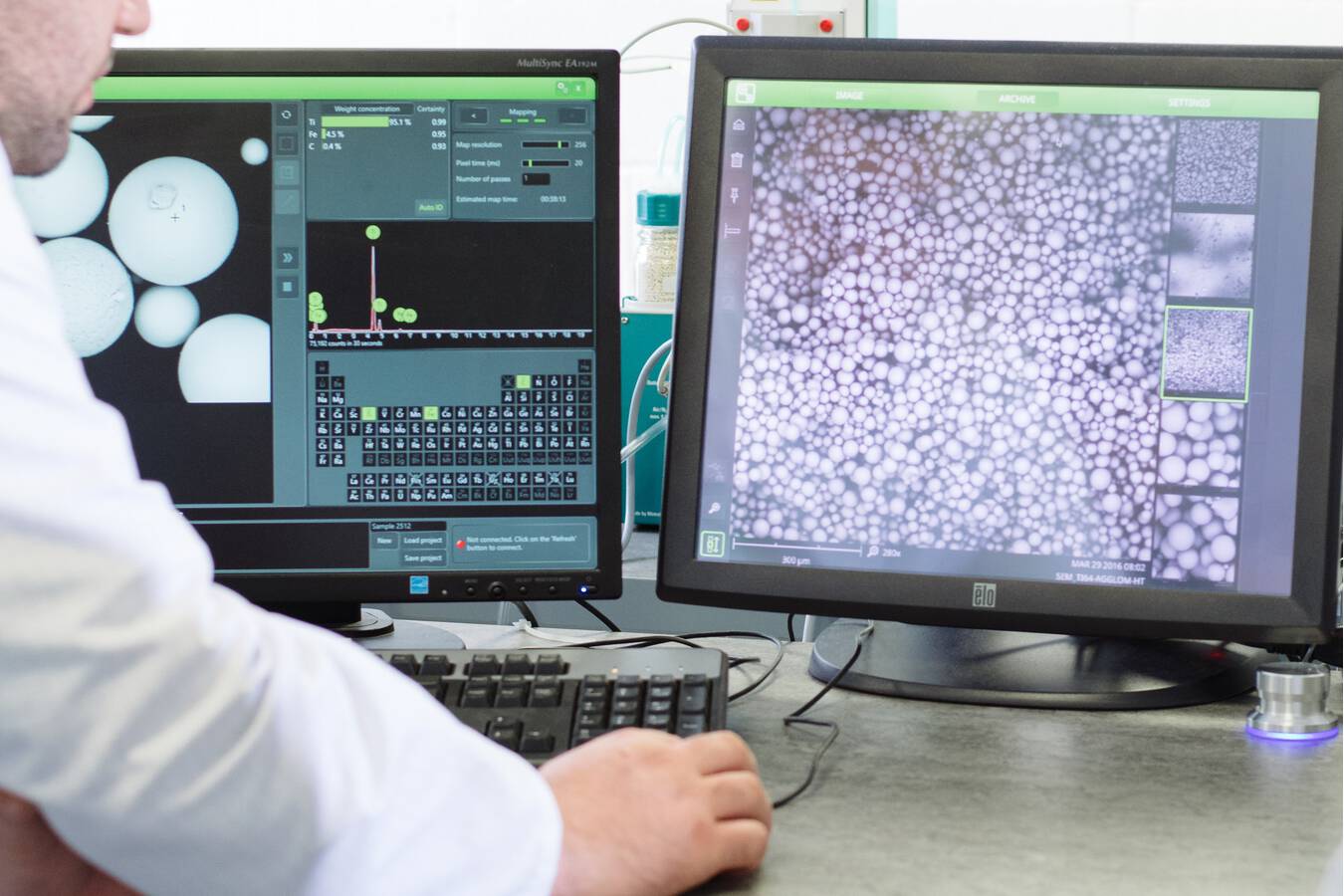

Neu in diesem Jahr ist, dass Dr. Hamid Salehi von der Universität Greenwich zusätzlich zu den Standardthemen Recycling und Qualitätsfragen, Verunreinigung, Oxidation, Pulverhandhabung und wichtige Sicherheitsüberlegungen seine Erkenntnisse über die neuesten Techniken bei der Prüfung der Verteilbarkeit und der Qualitätskontrolle von Schichten vorstellen wird.

Die Delegierten werden Folgendes erfahren

* Die neue Technik und das neue Instrument, die entwickelt wurden, um das Verhalten eines