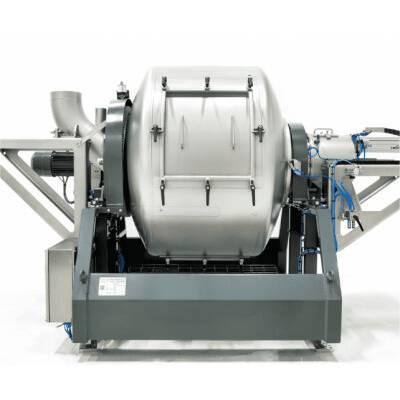

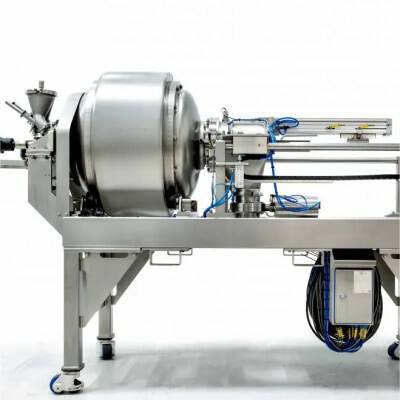

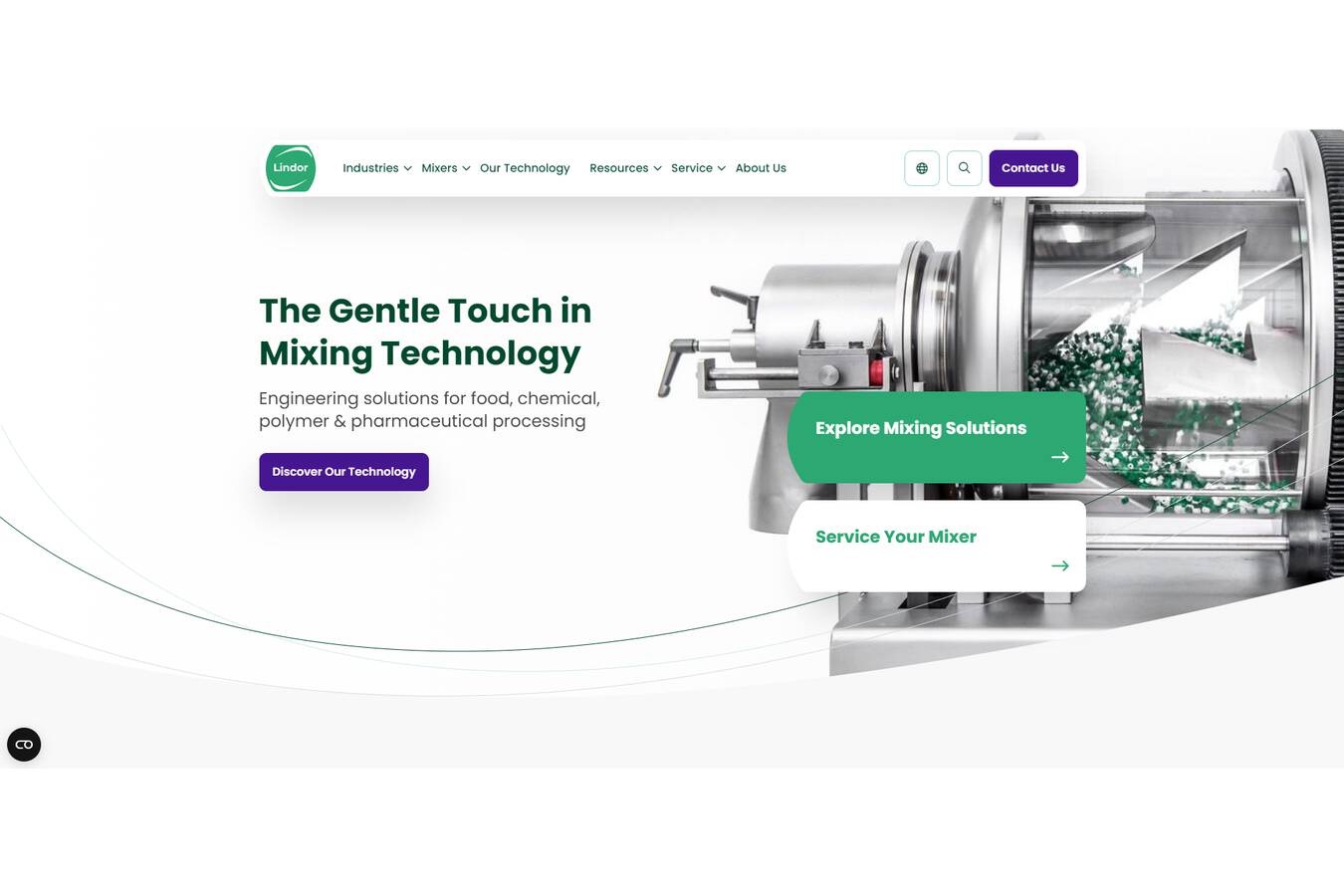

Lindor is a manufacturer of special mixers, coaters, impregnators and dryers which use gentle touch technology for processing powders, granulate and natural products. Each machine is customized for its specific application and client requirements.

Our machines are used around the world for manufacturing food, fine chemicals & special plastics as well as pharmaceuticals.

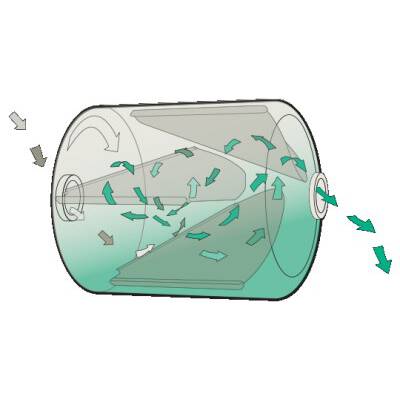

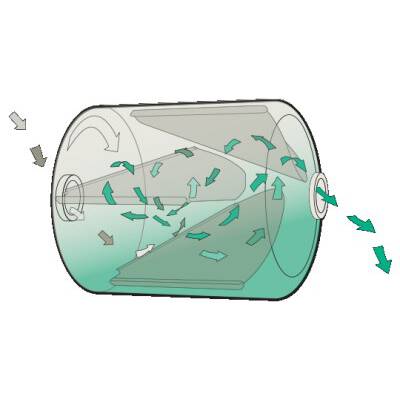

The unique mixing concept stands alone in that the design is entirely free of internal agitators. The outstandingly gentle but thorough mixing and blending effect is achieved by means of internally fixed, aerodynamically –shaped scoops.

Lindor mixers, because of their unique mixing principle, are especially suitable for processing even the most sensitive, delicate, and/or fragile particles, granulates and powders.

There is a range of available options:

- liquid injection,

- cryogenic mixing,

- air drying and cooling

- vacuum drying

- CIP systems,

- fully automatic controls.

These mixers come in a range sizes , with volumetric capacities ranging from 10 to 25,000 litres.

Products, services

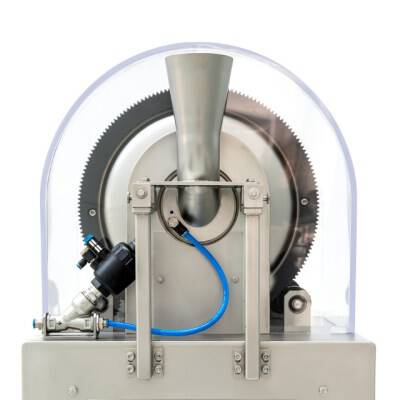

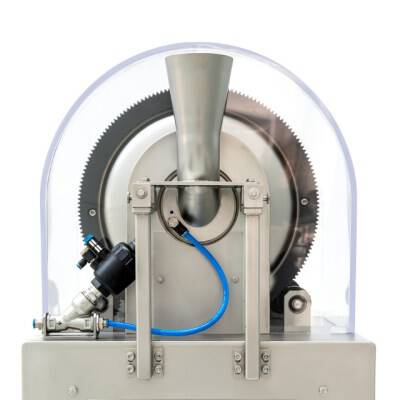

Blending, mixing - horizontal drum mixer, batch mixer, dry powder mixer, laboratory mixer

Mixers, mixing - horizontal drum mixer, batch mixer, dry powder mixer, laboratory mixer

Coaters, impregnators - cutting-edge liquid injection ensures precise and even liquid distribution, so perfect homogeneity and outstanding quality output is delivered

Heaters, Dryers, Coolers - advanced temperature control delivers ultimate efficiency by treating products while homogenizing simultaneously

Vacuum Drying, Coating - specially designed for production efficiency, perfect product homogeneity and excellent quality